What are the Best Uses for Alnico Magnets?

News

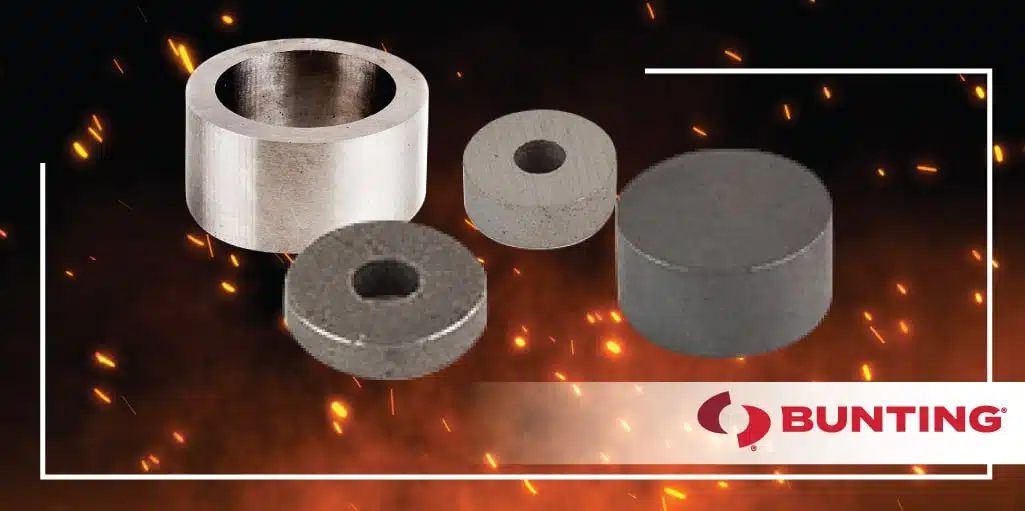

Alnico magnets are strong permanent magnets comprised of aluminum (Al), nickel (Ni), and cobalt (Co), hence the name “alnico.” Prior to the discovery of rare earth magnets, alnico magnets were the strongest permanent magnets available. Today, they remain highly popular magnets and are widely used in many different applications due to their strength, affordability, and temperature stability.

Alnico Can Handle the Heat!

The temperature stability of alnico magnets is one of their most desirable traits. They are the only magnets that can perform at “red hot” temperatures of up to 1000°F (about 535°C). As a result, alnicos are commonly used in electric motors, military and aerospace applications, sensors, and engineering applications. Overall, alnicos have the greatest temperature stability and are able to perform at the highest operating temperatures compared to any other magnetic material.

Another unique benefit of alnicos is that they are electrically conductive, which ceramic and ferrite magnets are not. They are also less brittle than rare earth magnets, while maintaining greater strength than ceramic and ferrite magnets. Alnico magnets are highly resistant to corrosion, and while surface treatments are not required, alnicos can still be easily plated.

Types of Alnico Magnets

Alnico magnets are most commonly available in grades 5 and 8, although other grades are available. Grade 5 cast alnico material is the most commonly used type of alnico material, and can be found in applications ranging from simple holding applications to complex rotating machinery. Grade 8 cast alnico has the highest temperature stability of any magnetic material currently available, and it boasts a 6.0 energy product combined with resistance to demagnetization. Grade 8 cast alnico can be found in motors, generators, computer components, transducers, and more.

Other types of alnicos are available as well, such as sintered alnico. Sintered alnico has slightly lower magnetic properties but significantly higher mechanical properties compared to cast alnico, and is used in applications that involve high-speed motion or require a shorter magnetic length. Sintered alnico can be manufactured to very close tolerances, and its fine grain structure means it has highly uniform mechanical strength and flux distribution. Sintered alnico is often used in applications such as sandwich-type holding assemblies, traveling wave tube stacks, torque transmitting devices, and reed switches.

BuyMagnets.com offers an enormous selection of alnico magnets in many different shapes, sizes, strengths, and grades. To speak to our engineers about selecting the perfect alnico project for your application, or to learn more about alnico magnets, contact us today.