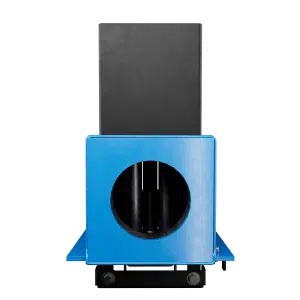

Drawer Magnets

From $1,014.30 – $1,374.25

Made to Order, 2-3 week lead time

Superior Contaminant Capture that Handles High Temperatures

Ever since 1964, Bunting® drawer magnets have been known as the best option on the market for superior contaminant capture in gravity free-fall applications. In the plastics industry, Bunting drawer magnets are the most popular choice for pairing with extrusion, injection, and blow molding equipment to ensure that all contaminant metal particles are captured and removed from the product flow. With over 100,000 Bunting drawer magnets in use today, these are the plastic industry’s most trusted, most used and most popular magnet to ensure product purity.

Bunting offers the most complete line of drawer magnets here. However, if you need a standard drawer magnet, order today for immediate shipment.

Bunting Drawer Magnets are designed to deliver the highest level of contaminant capture. Staggered rows of temperature-compensated, high intensity neodymium magnets instantly stop metal, purifying your product, before it enters your expensive extrusion, injection, or blow molding equipment. These super-strong neodymium magnets are powerful enough to capture and hold ferrous particles so small that they are invisible to the naked eye. These neodymium magnets have exceptional surface holding force, resulting in more complete removal of contaminants and less chance of “wipe-off,” referring to contamination falling off of the magnetic surface and re-entering the product stream.

These exclusive, highly refined drawer magnets are the only temperature-compensated rare earth magnets available for integration with injection molding machines. Bunting magnets are guaranteed not to lose magnetic strength when bolted to equipment operating at temperatures in excess of 175º F, compared to other rare earth drawer magnets that risk permanently losing their magnetic power at temperatures above 175º F. Bunting drawer magnets deliver strong magnetic energy that means guaranteed durability and less downtime for you – not to mention reduced screw wear and fewer plugged nozzles.

Standard Model Features:

• Temperature-compensated, high intensity rare earth magnets for superior high temperature operation and exceptional surface-holding force

• Two rows of 1” diameter tubes maximize magnetic circuit while allowing ample space for flow

• Rugged, 11-gauge stainless steel housing built to support symmetrical compression loads of 10,000 pounds

• Dust-tight welded housing for easy cleaning and durability

• Drawer gasket cut from ethylene propylene diene (EPDM) to resist heat aging and compression set, and offers much greater durability than sponge rubber

• Clear polycarbonate drawer front for easy viewing of product flow and captured contaminants

• High-torque nylon knobs resist breakage

• Superior cartridge geometry increases reach-out and holding power

• Available in 6” and 8” square.

If any modifications are required for your application, you will need to order a custom built model. Please contact our sales team for assistance.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Flange | 6 x 6, 8 x 8, 4 x 4 |

| Top Opening Diameter | 4.25, 6, 2 |

| Bottom Opening Diameter | 2.875, 5.5, 2 |

| Height | 10.5, 10.625, 10.875 |

Filter Results

| Part # | Flange | Top Opening Diameter | Bottom Opening Diameter | Height | Price | |

|---|---|---|---|---|---|---|

FF-08-SG | 8 x 8 | 6 | 5.5 | 10.875 | $1374.25 | QTY DISCOUNT PRICE |

FF-04-SG | 4 x 4 | 2 | 2 | 10.5 | $1014.3 | QTY DISCOUNT PRICE |

FF-06-SG | 6 x 6 | 4.25 | 2.875 | 10.625 | $1143.1 | QTY DISCOUNT PRICE |