New Pot Magnet Selection Guide

News

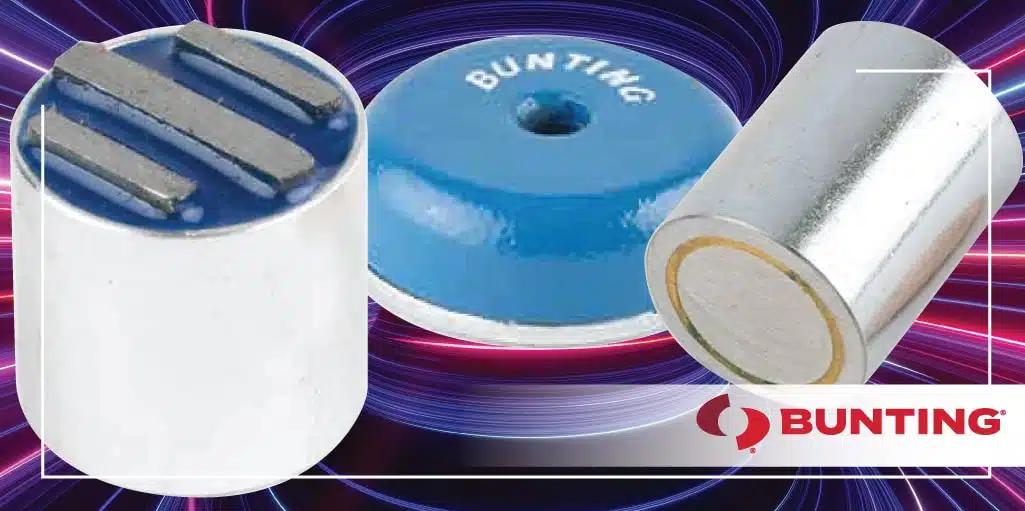

BuyMagnets.com is proud to offer a large selection of pot magnets to cater to the different needs of our customers. A “pot magnet” is a magnet that is housed inside a steel shell in order to increase the magnet’s robustness and protect it from corrosion and surface damage. Many different applications utilize pot magnets, so to assist you in selecting the best pot magnet for your application, we’ve created a helpful pot magnet selection guide.

The Selection Process

There are several things to consider when choosing a pot magnet. Different pot magnets have different features, including the magnetic material, the magnetic strength and performance, the way the pot magnet is fixed or mounted, the magnet’s finish or coating (especially for corrosive applications), and, of course, the dimensions of the pot magnet (diameter and depth).

Selecting the Mounting or Fixing Type

Pot magnets have different mounting and fixing types to provide you with different options for securing the pot magnet.

Countersunk Mounting (includes shallow pot magnets): Pot magnets featuring countersunk mounting have a countersunk hole in their magnetic front face in order to permit a simple countersunk screw to pass entirely through the magnet. A countersunk mounted pot magnet will have a flush finish on the magnet’s face and the threaded part of the fixing will be available on the other side of the magnet to provide for easy mounting.

Through Hole Mounting: Pot magnets featuring through hole mounting utilize a ring magnet in order to provide space for the head of the fixing to sit clear from the magnet. This allows the fixing to pass straight through the magnet, going through the face side of the magnet. A through hole mounted pot magnet will provide for a flush finish on the magnet’s face and the fixing’s threaded part will be easily available on the opposite side of the magnet.

Threaded Through Hole (Includes Limpet Pot Magnets): A threaded through hole pot magnet is designed to have a steel disc with a ring milled out to allow for a ring magnet to be easily inserted. Additionally, there is a tapped through hole that allows for a fixing to be threaded through the magnet. This through hole allows the fixing to be turned past the magnet’s face, allowing you to easily pull the magnet away from the structure it is magnetically holding itself to.

Internal Threaded Mounting (Includes Deep Pot Magnets): Pot magnets with internal threaded mounting have a threaded hole in the top of their pot that allows a fastener to be easily attached. The result is a pot housing that can contain more magnetic material, resulting in improved magnetic performance.

Internal Threaded Stud: Internal threaded studs allow for fasteners to be easily attached to the pot magnet. Because the stud forms part of the pot magnet’s outer section, it allows for a larger magnet to be housed within the pot. A larger magnet allows for improved magnetic performance.

External Threaded Stud: Pot magnets with an externally threaded stud allow the pot magnet to be easily screwed into existing tapped holes. It is also possible to screw other threaded attachments directly onto the pot magnet. Because the stud is part of the pot magnet’s outer design, a larger magnet can be housed within the pot in order to achieve improved magnetic performance.

Selecting the Magnet Material

BuyMagnets.com stocks pot magnets in three different types of magnetic material: alnico, ceramic/ferrite, and neodymium.

Ceramic/ferrite magnets are sought out for their deep, strong magnetic force as well as their numerous other benefits. Some of the other featured traits of ferrite magnets are longevity, corrosion resistance, low price point, and ability to operate at temperatures up to 250 °C.

Alnico magnets are stronger than ceramic/ferrite magnets, but with the same resistance to corrosion. Alnico magnets are capable of maintaining a strong magnetic field even when exposed to extreme temperatures as high as 450 °C.

Neodymium magnets are rare earth magnets, and the most powerful magnetic material available. While they offer intense strength, they must be coated in order to resist corrosion, and most are only able to operate at temperatures up to 80°C. However, special high temperature neodymium magnets do exist.

Selecting the Finish or Coating

There are multiple different coatings and casing specifications available for pot magnets.

Chrome plating and nickel plating both provide excellent resistance against corrosion.

A stainless steel coating offers the highest level of corrosion resistance, and is recommended for highly corrosive environments, such as those found in marine applications.

Some magnets—namely, alnico—may be painted, but this provides little protection against corrosion and is namely done to achieve aesthetic specifications.

Rubber coated magnets provide excellent resistance to shear and sliding, and also protect the surface you are attaching the magnet to. For example, a rubber coated magnet will not damage painted or highly polished surfaces.

Selecting the Size and Depth

To achieve optimum performance in a given application, both the diameter and depth of the pot magnet must be carefully considered. As a general rule, larger magnets result in greater performance. However, due to the varying strength in magnetic materials, this is not always the case. For example, a smaller neodymium magnet can easily outperform a larger alnico or ferrite magnet in terms of strength.

The Pull Force of the Pot Magnet

A “pull force” relates to a magnet’s strength and performance when subjected to a direct pull test. By providing a pull force value for each of our magnets, customers can easily compare the strengths of different pot magnets. However, it is important to note that any magnet’s pull force will be reduced as air gap increases (the space between the magnet and the surface it is being attracted to). Additionally, magnets perform best when the surface they are being attracted to is smooth and even.

Pot Magnet Applications

Pot magnets can be found in many different applications, including:

- Point of sale displays

- Marketing and exhibition displays

- Marine

- Window dressings

- Door, gate, and cabinet clamps

- False ceiling clamps

- Banners and signs

- Torque limited seals

- Jigs and fixtures

- Lighting fixtures and assemblies

- Industrial fixings

- Retrieval magnets

For more information on selecting the best pot magnet for your application, contact BuyMagnets.com today.