Magnets Bring Vinyl Records to Life

News

In the age of digital downloads, streaming, and CDs, Vinyl has made a surprising comeback over the last decade. Vinyl got its groove back in the 2010s and hasn’t slowed down since. In 2023, Vinyl records topped CDs in physical media sales for the first time in over 30 years. It’s not just legacy artists re-selling their albums on vinyl to new fans. Current artists like Jack White and Taylor Swift are making vinyl releases a priority. There’s a certain “cool” factor to vinyl that can’t be replicated in other formats. Warmer sounds, bigger cover art, and becoming a part of “record culture” with other like-minded audiophiles. Did you know that none of this is possible without magnets? Let’s dig into how magnets from BuyMagnets play a crucial role in this multi-million-dollar industry.

How do Magnets Help Vinyl Discs Get Their Groove?

Step 1: Mastering the Groove

Once an artist lays down their tracks, the next step is to transform the audio into the physical grooves on a vinyl record. This process, known as mastering, involves cutting a master disc with a lathe.

Magnets come into play during mastering through the use of a cutting head. This head contains a coil of wire surrounded by a powerful magnet. As the audio signal passes through the coil, it interacts with the magnetic field, causing the cutting stylus to vibrate. These vibrations are etched into the master disc, creating the characteristic grooves that produce the tasty sounds coming out of your speakers.

Step 2: Replicating the Sound with Magnets

Once the master disc is perfected, it’s time to create the stampers that are used to mass-produce vinyl records. This is where magnets make another appearance in the form of nickel plates.

The master disc is coated with a thin layer of nickel, and the magnetic stampers are created by placing these nickel-coated masters in a solution containing tiny magnetic particles. When magnets are applied to this solution, the particles align themselves with the magnetic field, effectively replicating the grooves of the master disc. This results in the creation of the stampers that are used to press vinyl records.

Step 3: Preparing the Vinyl Material for Production

BuyMagnets customer Steve Polutnik, Founder of Smashed Plastic, uses magnetic grates in his vinyl record production process to safeguard against unwanted ferrous metal contamination. Positioned inside of a plastic pellet hopper, these grates utilize powerful magnets to attract and capture any stray metal particles that could potentially interfere with the pristine grooves of the records. Steve says they learned the benefits of magnetic grates the hard way — by not using them. Six years ago, metal debris unfortunately made its way into their vinyl production runs, which resulted in very costly and time-consuming mistakes. Thanks to magnetic separation technology, Smashed Plastic can ensure their final vinyl product remains free from imperfections caused by ferrous metal debris, while also preserving the integrity of the recording itself.

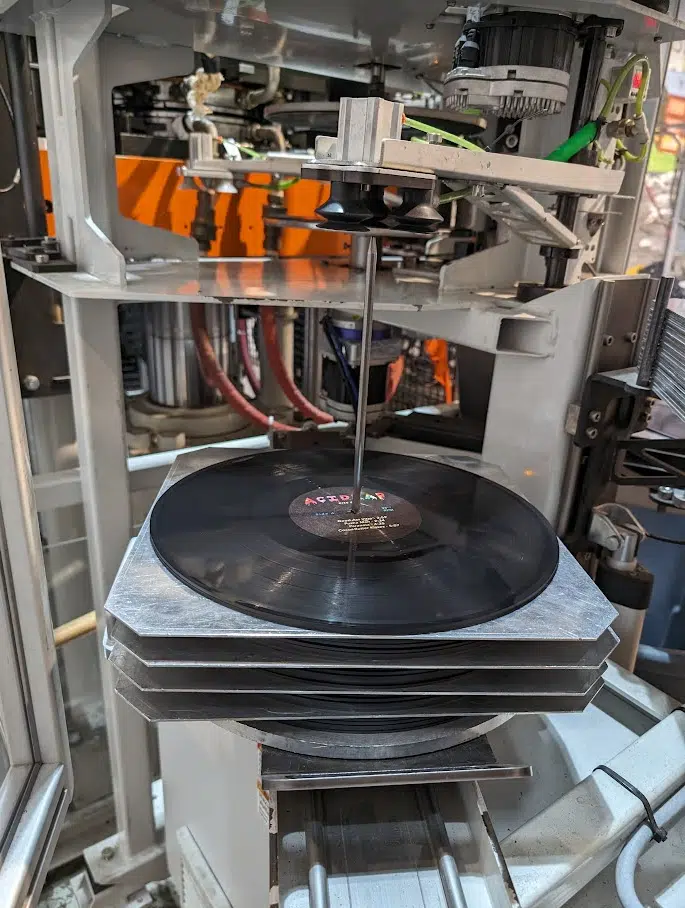

Step 4: Pressing the Vinyl

Now equipped with the stampers, it’s time to press the vinyl. The stampers are placed on either side of a vinyl disc, and a hydraulic press applies heat and pressure to create an exact replica of the grooves from the master disc. Magnets in this process are indirectly responsible for ensuring the faithful reproduction of the audio. The alignment of the magnetic particles determines the accuracy of the grooves on the vinyl. During the pressing process, excess vinyl is trimmed off. Steve and the Smashed Plastic team then run it through another magnetic grate to ensure no ferrous metal debris makes its way back into the regrind material.

The Grand Finale

As the vinyl emerges from the press, it carries with it the magnetic imprint of the music within its grooves. When you spin your new record and drop the needle, the turntable stylus glides along these grooves and senses the subtle variations in the magnetic field. It then translates them into the tunes that are currently jamming out from your speakers.

Vinyl is back with a vengeance, but it wouldn’t be nearly as cool (or even possible) without the technology of magnets and magnetic separation. Contact the experts at BuyMagnets and let’s talk about how our magnets can help your Vinyl Record Processing operation.